China One-Stop Service OEM Factory Custom Forging/Machining/Casting High Precison Auto Parts in Steel

Product Details

| Item | Steel Parts for Auto |

| Surface Preparation | Sand Blasting, Plating, Galvanized, Spray-Paint, Passivating, Polishing, Electrophoresis, Machining, etc. |

| Surface Roughness | Ra0.05∼Ra50, depends on Customer’s Requirements |

| Process | Mold Making, Casting, Machining, Surface treatment, Inspection, Packing, Loading |

| Casting tolerance | CT5-CT8 |

| Casting blank weight | 0.01kg-3000kg |

| Coating | Electrophoresis Coating |

| Machining | Lathing/Milling/Turning/Boring/Drillig/Tapping/Grinding, etc |

| Machining tolerance | 0.01mm |

| Design software/ formats | 3D, Auto CAD (IGS,DXF,DXF,DWG,STP, STEP,STL,X-T)/Soild Works/CAXA/Rhino/CATIA/SIMIO/ALIAS/ARENA/Unigraphics, etc |

| Certification | ISO9001:2015, CE, SGS, RoHS, IATF16949 |

| Inspection Equipment | Test equipment: Spectrum Analyzer, Hexagon CMM, Hardness test equipment, Tension test machine, E-coating testing equipments, Metalloscope. |

| Dimension Inspection | Coordinate Measuring Machine (CMM), Calipers, Height Gauge, Micrometer Calipers, Inside Caliper Gauge, Angle and R Gauge, customized gauge, etc. |

| Application | Automobile, Car, Heavy Truck, Light Truck, Commercial Vehicle , Forklift, Construction Machinery/Truck/Vehicle, Farm Vehicle/Machinery/Truck, Agriculture Machinery/Truck/Vehicle, Mining Machinery, Marine Hardware, Train, Railway, Petroleum Machinery, Engineering Machinery, Shipbuilding, Power Equipment, etc. |

| Package | Bubble plastic bag/polybag/pallet/wooden case, etc. |

| Trademark | OEM |

| Origin | China |

| Loading Port | Qingdao Port |

| Annual Supply | 1000000 Pieces |

| Sample | Available |

| Sample production cycle | 30-45 Working days. |

| OEM/ODM service | Available |

Casting process: Sand casting.

Secondary process: Painting, CNC machining, machining center , Drilling, Tapping, deburring and packaging.

Quality control: IATF16949 and ISO 9001 certificates, PPAP documents.

Management Software: ERP, OA, Pro-E, PDM, BOM.

Material: Gray Iron, HT200, HT25, HT300, HT350 GG14, GG20, GG25, GG30 EN-GJS-150, EN-GJS-200, EN-GJS-250, EN-GJS-300 ASTM A48 class 25, class 30, class 40, class 50, class 60

Ductile Iron(Nodular Iron): QT400, QT450, QT500, QT600, GGG40, GGG50, GGG60 60-40-18, 65-45-12, 70-50-01, 80-60-03

Alloy Steel:1020, 1045, 4140, WCB, LCB

Stainless Steel: SS304, SS304L, SS316, SS316L, CF8M, CF-8,

Production Process: casting and CNC precision machining

Our comparative advantage

1* Mature one-stop service system.

We provide real one-stop service for all customers

(1)we are the source manufacturers, and our price has an absolute advantage.

(2)We have our own technology department to solve all-round problems related to product technology.

(3)We have a complete production line, products from raw materials to finished products are under our control.

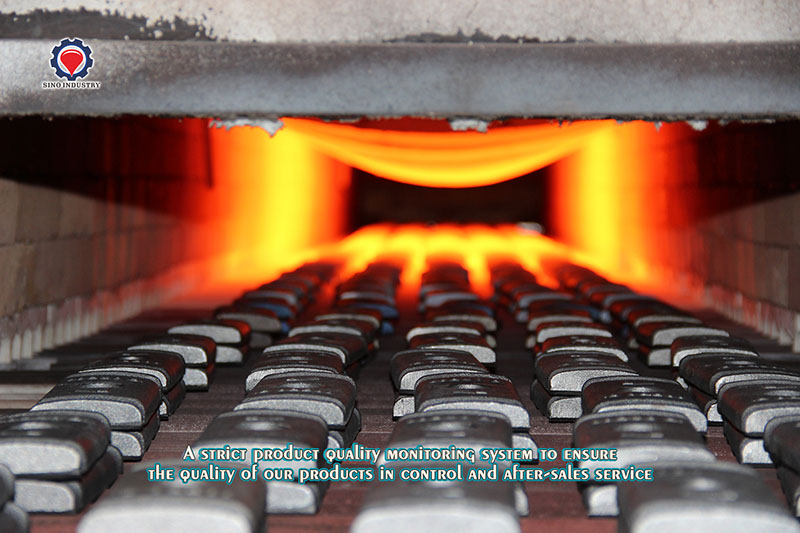

(4)We have a strict product quality monitoring system to ensure the quality of our products and after-sales service.

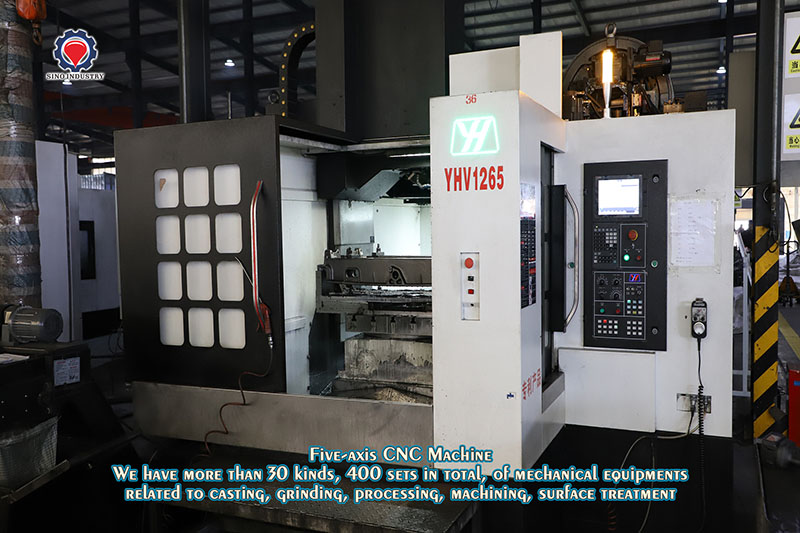

2* Modern machinery and patented equipment.

We have more than 30 kinds of mechanical equipment related to casting, grinding, processing, surface treatment, etc., more than 400 sets in total, including 60 sets of four/five-axis machining center (CNC) and 2 sets of digital special machines designed with double main axle boxes. Our equipment has significantly improved production efficiency and product quality.

3* Sufficient production capacity.

We supply more than 110000 tons of goods to more than 12 clients in 2021. Under the supervision of a production system, We not only ensures sufficient supply capacity, but also achieves 98% delivery efficiency.

4* Wide application of products

The castings produced by us are widely used in various industries, such as construction vehicles, trains, railways, forklifts, agricultural machinery and other mechanical equipment. We can produce all kinds of castings according to customer's drawings and customer's requirements, including but not limited to the following:

Steel parts, precision steel parts, stainless steel parts, carbon steel parts, alloy steel parts, metal parts, metal processing, metal stamping, metal punching, metal molding, stamping parts, punching parts, turning parts, molding parts, machining, cnc machining, machining parts, cnc machining parts, cnc parts, machining foundry, casting foundry, steel stamping, steel punching, steel turning, steel molding, professional casting, precision casting, precision stamping, precision punching, precision turning, precision molding, casting manufacturer, casting manufactory, custom casting, precision machining, precision casting steel, sand casting, die casting, lost wax casting, investment casting, gravity casting, nonstandard parts, auto parts, spare parts, auto spare parts, car spare parts, truck spare parts, lorry spare parts, automotive spare parts, automobile spare parts, automotive parts, automobile parts, car parts, truck parts, lorry parts, heavy truck parts, heavy-duty truck parts, transport truck parts, heavy transport vehicle parts, vehicle parts, forklift parts, farm vehicle parts, farm truck parts, farm machinery parts, farm machine parts, agricultural vehicle parts, agriculture vehicle parts, agricultural truck parts, agriculture truck parts, agricultural machinery parts, agriculture machinery parts, agricultural machine parts, agriculture machine parts, combine harvester parts, tractor parts, trailer parts, mining equipment parts, mining machinery parts, mining machine parts, mining truck parts, mining vehicle parts, industrial parts, industry parts, equipment parts, machinery parts, machine parts, mechanical parts, device parts, facility parts, engine parts, motor parts, pump parts, pump body, pump shell, pump housing, pump casing, pump cover, water pump, impeller, pump impeller, hydraulic pump parts, pump spare parts, water pump parts, hydraulic spare parts, stainless steel pump, centrifugal pump, slurry pump, sewage pump, electric pump, submersible pump, high pressure pump, chemical pump, pressure pump, water pump set, self-priming pump, garden pump, deep well pump, oil pump, fountain pump, pond pump, mud pump, single suction, fuel pump, diesel, water pump, vacuum pump, auto pump, car pump, automotive pump, automobile pump, vehicle pump, truck pump, lorry pump, valve parts, valve body, valve shell, valve casing, valve housing, gate valve, ball valve, connector, solenoid valve, pipe fittings, control valve, floating ball valve, pneumatic valve, industrial valve, gas valve, flange gate valve, directional valve, hydraulic control valve, butterfly valve, gearbox, gearbox parts, gearbox body, gearbox shell, gearbox casing, gearbox housing, oil cylinder, cast iron, cast steel, cast iron parts, cast steel parts, casting parts, iron casting, steel casting, metal casting, cast metal parts, sand cast parts, sand casting parts, cast machine parts, cast machinery parts, machine spare parts, hardware, coupling, marine hardware, precision parts, high performance parts, high quality parts, truck bracket, lorry bracket, engine bracket , motor bracket, steering gear bracket, leaf spring bracket, balanced suspension, suspension system, suspension arm, steering knuckle, vehicle bracket, bumper bracket, exhaust pipe, exhaust pipe manifold, diesel engine, etc.

5* Perfect product information tracking

After the product is inspected in terms of quality, we will record the products produced by different batches of raw materials and archive the production information of each batch of products, each of our products is marked with raw material batch number and factory production code. Our purpose is to find the root of the problem accurately when the customer has the demand for product quality and after-sales, and find the same batch of products to ensure that these products are free of problems.

Why Choose Us ?

1. Real One stop service:

We have 5 own factories and 50+ sub-contractors located in different areas of China to offer you real one-stop manufacturing and purchasing services to help you save time and reduce procurement cost.

2. Your eyes in China:

Our commitment to quality permeates from quoting, scheduling, production, inspection to deliver into your warehouse, our QC team will remark the errors if has on QC documents for your checking before delivery as your 3rd party.

3.Your R&Dconsultant:

With professional engineers team and 40 years manufacture experience ,we would help you work out problems during new parts' development, optimize design and recommend the most cost-effective solution.

4. Your Emergency Solver:

With continued grown factories team and our QC teams located in different areas, if customers need to expedite the delivery, we would be able to adopt another factory to produce together immediately.

5. Quality Guaranty:

More than 40 years experience in casting/machining industry, with 60 experienced technical engineers and 800 skilled workers. Advanced testing equipments, strict quality control system, to ensure us constantly, stably to provide high-quality products for customers.

Our Advantages

1. We are a professional OEM manufacturer.

2. We have experienced engineers and quality control team as our strong backing.

3. High quality, competitive price, quick response is our mission.

4. Professional technical support.

5. Agreed delivery time.

6. Strict quality control process.

7. Cost-Effective.

8. Rich experience in mould design and production.

9. ISO/ERP system guarantee.

Our Services & Strength

ISO 9001:2015 and IATF16949 certified factory utilizes ongoing employee training, automation, continuous process improvement and innovation to maximize the quality, reliability, and cost-effectiveness of your components.

Parts are carefully examined throughout the production process at multiple quality control checkpoints and all shipments are thoroughly tested and inspected before they are released to your facility. As a result, our team has been able to consistently maintain a nearly 0% external part reject rate that has enabled many of our customers to eliminate the costly and time eroding process of inbound part inspection.

Skilled craftsmen, with years of specialized knowledge and understanding, fabricate parts to specified tolerances. We're confident that we offer a far more cost-effective and low-risk solution than our competitor. So when the success of your business depends on the ultimate in quality control, precision, timeliness, and service, you can trust your metal working needs to us.

Packaging

Packing & Delivery:

Inner Packing →Strong & waterproof plastic big is packed inside, to keep the product in safe condition.

Or as customer requests.

Outer Packing →Multilayer wooden box with strong bandages, used for standard export package.

Or customized as per customer's requirements.

FAQ

We are a professional manufacturer with over 15 years' export experience for designing and producing vehicle machinery parts.

If you need, we are glad to offer you samples for free, but the new clients are expected to pay the courier cost, and the charge will be deducted from the payment for formal order.

Yes, we can make casting according to your drawing, 2D drawing, or 3D cad model. If the 3D cad model can be supplied, the development of the tooling can be more efficient. But without 3D, based on 2D drawing we can still make the samples properly approved.

Yes, we can make measurement based on your samples to make drawings for tooling making. We have special technology and skill to solve and handle special material, special structure, special defect and special processing.

We have spectrometer in house to monitor the chemical property, tensile test machine to control the mechanical property and UT Sonic as NDT checking method to control the casting detect under the surface of casting.

Each batch of products from raw materials to finished products will be tested in the laboratory to ensure that the quality is up to the standards.

Each batch of finished products will be carried out spectral inspection.

For specific products tensile test will be conducted to ensure the tensile strength of products up to the standards.

30% T/T in advance, balance before shipment, or as per negotiation.

● Checking the raw material after they reach our factory-----Incoming quality control(IQC)

● Checking the details before the production line operated

● Have a full inspection and routing inspection during mass production----In-process quality control(IPQC)

● Checking the goods after they are finished----Final quality control(FQC)

● Checking the goods after they are finished----Outgoing quality control(QC)

● 100% inspection and delivery before shipment